The Control of Vibration at Work Regulations 2005, a regulation that all business should comply with, it states that we should ‘’Protect workers’ health & safety from vibration exposure due to vibratory equipment transmitted by hand contact” it aims to ensure that employees do not experience harm to their health due to hand-arm vibration.

As an employer, you should be focused on managing and mitigating the risks associated with exposure to vibration, and taking all the necessary steps you to reduce the risks to be ALARP.

But, the challenge is, without continually measuring and monitoring the exposure levels how can you accurately take charge of HAV (hand arm vibration) Monitoring in your business?

You can use manufacturers data and then add the K factor, use assumed data which is accurate only at the time it was measured, use tool timers based upon the values above and ask the users to tell you how long they’ve used the tools for and then use the HSE ready reckoner…..it isn’t easy nor does it accurately identify the specific area of exposure risk, only that the whole duration of the task MAY be a risk.

Relying on “guesstimated” data isn’t enough when it comes to preventing life changing disabilities which may not manifest in their entirety for several years and, which can result in fines and compensation claims against employers. In recent years it isn’t uncommon to see fines over £200,000, a huge cost that could have been avoided if they’d taken the correct actions to achieve ALARP. By adopting HAV Monitoring and measuring as a continuous programme the guidance would have been there to achieve ALARP or even eliminate the risk totally.

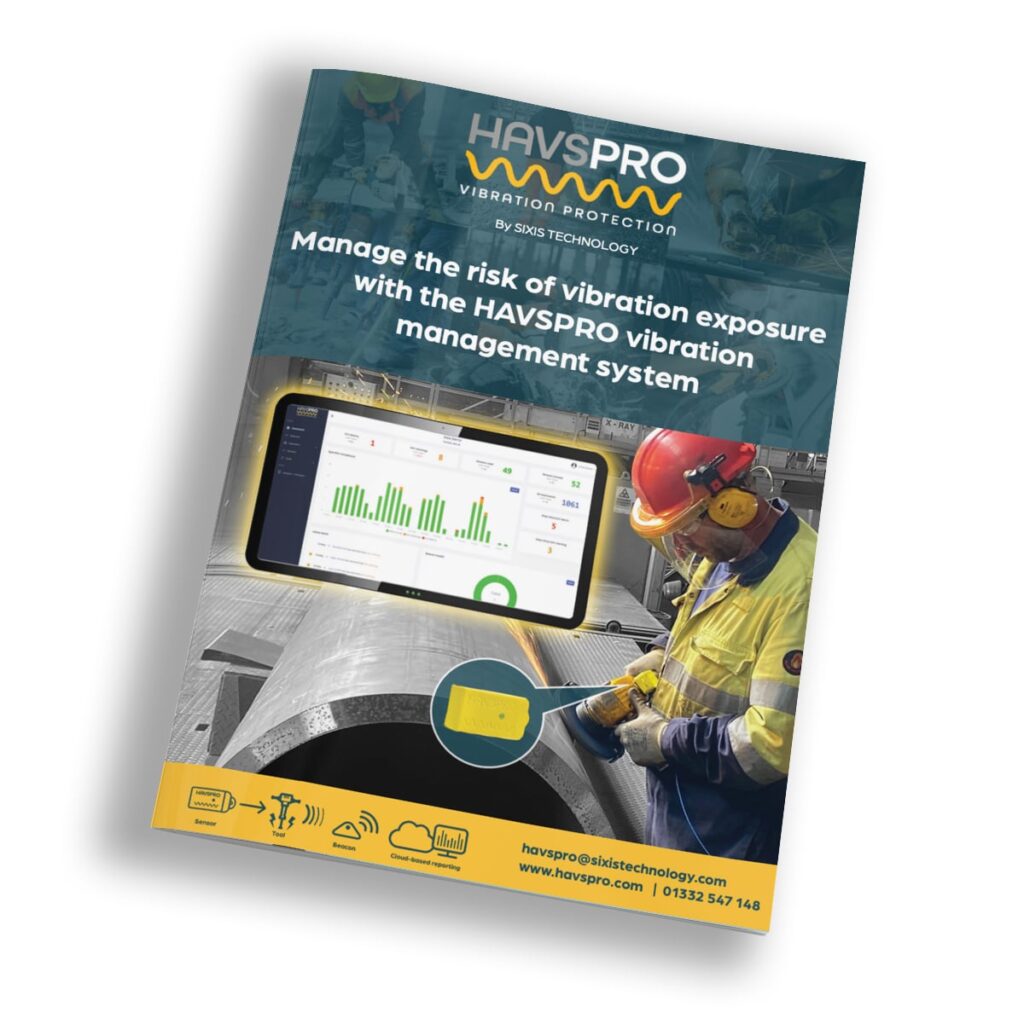

HAV Monitoring with HAVSPRO

With our simple, accurate and cost-effective system, continuous measuring and monitoring each individual user, tool and activity allows accurate tracking of the vibration levels each individual team member is exposed to through every task and even guides to offer clear identification of rogue tools or consumables that without continual HAV Monitoring and measuring would not have been possible.

The operator simply clicks the sensor onto a holster which is mounted onto the tools, does the job and removes, then onto the next tools etc. Each specific task is recorded allowing then analyse of each step and guides to an understanding of where the actual risks are, based upon FACTS, not guesstimates.

Accurate data drives informed data driven decisions which can be used to create effective risk assessments and reassuringly, gives accurate guidance in achieving ALARP, with the facility to record your findings and actions on the cloud-based reporting platform.

Are you ready to take HAV monitoring seriously in your business? If you are, complete the form below to find out more.