When managing the risk of vibration exposure in the workplace, as per the Control of Vibration in the Workplace 2005, the HSE clearly and frequently state that you should apply the hierarchy of controls.

When managing the risk of vibration exposure in the workplace, as per the Control of Vibration in the Workplace 2005, the HSE clearly and frequently state that you should apply the hierarchy of controls.

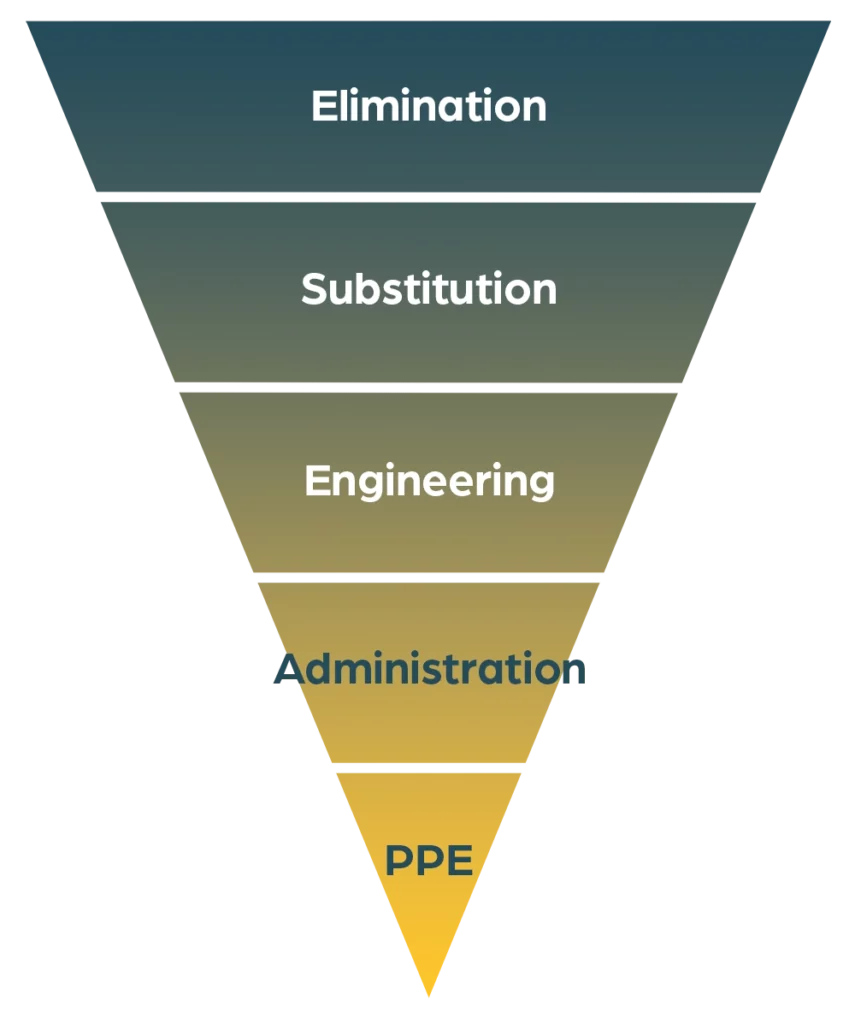

The hierarchy of controls for the vibration regulations is similar to that found in lots of other health and safety regulations, and are outlined in the diagram.

Elimination

The starting place, when using the hierarchy of controls to manage the risk of HAVS in the workplace, is the widest part, because it is the most effective solution and will reap the biggest rewards. This model asks you to look for any possibilities or opportunities to eliminate vibration exposure. If you can eliminate ALL vibration exposure through such measures as replacing all hand-held tools with remote control equivalents or not using vibrating tools at all, then your vibration risk management is zero and your task is complete. There is no risk of vibration related ill-health such as HAVS and if a HSE inspector asks about how you are managing vibration exposure then you can say ‘we have no vibration exposure, it has all been eliminated’. However, as we all know, eliminating the risk entirely from your business is rarely possible, so once you’ve implemented as many ‘elimination’ measures as are practical, you should look at substitutions.Substitute

The HSE recommend that, if you cannot eliminate the source of hand arm vibration, then finding tools that can do the job efficiently, but which have the lowest vibration magnitude will help you to reduce the risk from vibration exposure.

Many manufacturers are now entering the electric power tool market with Hilti, Milwaukee and Stihl all having their own ranges of electric power tools that they are supplying to the trade.

The biggest driver for this is the need to reduce carbon emissions but it also means there are lots of options when it comes to finding an alternative tool that emits lower levels of vibration.

I word of caution here – tools that emit lower vibration levels may not always reduce vibration exposure. This is because they may require the user to operate them for a longer time period than a higher vibrating substitute. This could potentially lead to the operator being exposed to higher vibration throughout the day.

And perhaps a second word of caution when looking to invest in electric power tools – battery powered tools do NOT guarantee lower vibration levels are going to be emitted. Always check what the vibration exposure would be and compare substitutes using the HSEs ready reckoner before you invest in substitute tools.

However, unless you are continuously monitoring and measuring vibration levels, in real-time as they happen, how can you be sure that your operatives aren’t still being over-exposed using the substitute tools? With HAVSPRO, you can be sure your staff are always aware of there exposure limits, as are you, as they manager or employer.

Engineering

This is an interesting step in the hierarchy because it is where technology can play such a significant part in providing solutions that genuinely reduce or eliminate vibration exposure.

Examples include remote controlled equipment such as the range of Wacker Neuson vibratory plates or, in other industries, the remote controlled lawn mower.

The research and development going into solutions that reduce or eliminate vibration is incredible and new innovations are coming onto the market all the time.

However, unless you are continuously monitoring and measuring vibration levels, in real-time as they happen, you can never be 100% confident that you are managing the risk of HAVS for your workforce. This is where HAVSPRO is a game-changer!

Administration

We are approaching the sharp end of the control measures now and as we do so the effectiveness of them declines.

The administration controls look at how you can reduce vibration magnitudes through better management on a day-to-day basis. This can include job rotation, job allocation, working practises, reducing maximum exposure times and incentivising staff to work to reduce their overall daily exposures when working.

This step in the control hierarchy relies heavily on you having a measuring and monitoring system that gives you (and your staff) the data you need to make effective, informed decisions. If you haven’t got continuous vibration exposure data as it is happening in your specific business, how can you change working patterns or tool choices or set limits that are safe and effective?

The HSE will always look at the measures you are taking to reduce magnitude rather than reduce exposure so simply reducing the amount of time on a particular tool isn’t enough to be managing the risk of vibration exposure.

Reducing vibration magnitude is more effective than reducing exposure time.

PPE

There are many vibration gloves on the market that claim to reduce the risk of vibration levels but the truth is, they only keep the hands warm which reduces the speed with which vibration levels will affect you. The science tells us that cold hands will be affected by vibration levels quicker than warmer ones, but regardless of temperature, vibration levels are not reduced by gloves. The regulations, updated in 2019 state “Anti-vibration gloves cannot be relied upon to provide protection from Vibration.”

The vibration regulations also say “…the employer shall assess whether any employees are likely to be exposed to vibration at or above an exposure action value or above an exposure limit value.”

Only HAVSPRO takes the guess work out of all these measures and makes sure you are in line with the Control of Vibration at Work Regulations 2005 because the data produced means you can make informed decisions when looking to implement ANY of the hierarchy of controls.

Take the guess work out of managing HAVS in the workplace with HAVSPRO – download our brochure…

Download the HAVSPRO Brochure

Discover how HAVSPRO monitors vibration levels accurately and triggers alerts to protect your staff and organisation against the risks of HAVS and WBV (whole body vibration).

It monitors individual tool vibration levels and the exposure each person has to it.

HAVSPRO then collates all this data and creates customisable reports to help you prevent overexposure.

Find out everything you need to know in our brochure – simply complete the form!

Find out more about HAVSPRO and how it can help you protect your staff and business: 01332 547 148 or you can download our Employers Guide to HAVS