When conducting your HAVS risk assessments, there are 2 main pieces of information that are used to assess risk: vibration magnitude and exposure time. Typically, there are two types of vibration magnitude data that can be used; assumed data or continuously measured and monitored data.

The issue of using assumed data verses continuously measured and monitored data is an ongoing debate in Health and Safety circles.

By law, every organisation that exposes operatives to vibration, hand-arm or whole-body, has to reduce the risk posed by this exposure to as low as reasonably practicable (ALARP) – and the first step is to conduct a risk assessment for each tool or equipment that could pose a risk to the operative from the vibration emitted.

But risk assessments are far from simple and when assessing the risk posed by vibration, the data that goes into them makes a huge difference to the outcome.

We take a look at some of the differences between using assumed vibration data and continuously measured and monitored data when assessing the risk posed by vibration emitting tools or machinery.

Assumed Vibration Data

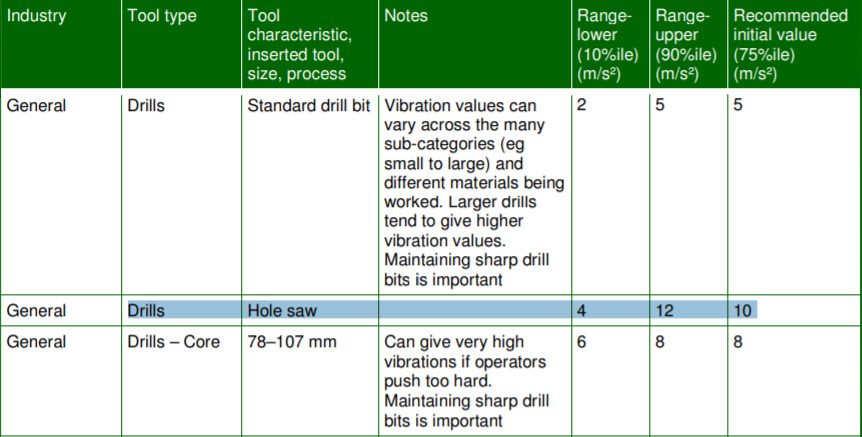

There are four main sources of assumed vibration data that can be used to create your risk assessment:

- The manufacturers emission data – it is a legal obligation for tool manufacturers to provide this for every tool.

- The HSEs source of vibration magnitude data document (dig.1).

- Vibration magnitude data from a limited period of monitoring which is then usually put on a label or tag that is attached to the tool.

- Library values supplied by other companies.

The problem with using any of these assumed vibration data sources as part of your HAVS risk management strategy is that there are so many variables that can effect vibration magnitude.

This means the values you are using to calculate exposure in HSE points may not give you an accurate representation of the exposure the operatives are actually experiencing. The consequences of which may only surface in the future.

Another important feature of this type of reactive strategy, is that in some cases it highlights the risk when the exposure points are calculated into HSE points and NOT at point of exposure. This means the exposure or over-exposure has already occurred making any resulting actions or control measures reactive – one could argue, the damage is done. And is this strategy allowing you to manage the risk of vibration exposure to ALARP?

Arguably the biggest problem with using assumed vibration data is that is means you are basing risk-reducing actions and decisions on probable data and not accurate data.

This leads us to the legal holes that start to appear with the use of assumed vibration data compared to continuously measured and monitoring exposure.

This leads us to the legal holes that start to appear with the use of assumed vibration data compared to continuously measured and monitoring exposure.

In order to comply with the Regulations, an employer is required to eliminate or reduce the amount of vibration that an employee is subjected to. In order to comply with the regulations, you only need to assess the risk posed by vibration tools or equipment using assumed data as mentioned above.

However, in assessing the risk, and managing it to ALARP, the estimate must be appropriate and sufficient to comply with the statutory obligations. The legal argument begins to unfold when the degree of certainty reduces as it does with assumed vibration data. This means that employers will have less certainty about their own legal position or that their employees are being protected as well as they could be.

The HSE state that continuously measuring and monitoring vibration exposure is a waste of a companies time and money, but now that technology has made this level of certainty a very viable option, why wouldn’t they use it? Moreover, how long will it be before the legal argument for using it is more compelling than that for using less certain assumed vibration data?

Continuous Measuring and Monitoring of Vibration Data

The HAVSPRO system gives organisations the ability to measure and monitor vibration levels on the tool, in real-time, whilst proactively managing exposure levels with a text and email alert system.

Available at a price that positively compares to the cost of paper- based processes, hiring a consultant or company to perform your own vibration magnitude testing, or using another technology-based system on the market – but you get so much more…

The HAVSPRO system allows you to meet your legal obligations whilst protecting your operatives and business from the risk posed by vibrating tools and equipment. With the ability to control and limit individual vibration exposure levels, you can protect even the most vulnerable operatives, further reducing the amount of HAVS cases.

Continuous measuring and monitoring of vibration levels gives you more than just peace of mind that you are protecting and preventing as many HAVS cases as possible, it also allows you to manage tool attrition and usage from within the tailored dashboard.

The detailed reports for individual tools give you tool management capabilities, alongside the ability to build evidential business cases.

HAVSPRO gives you data-based decision-making from a single, convenient cloud-based system. The data is your data, available 24/7 and retained on the cloud or downloaded into your files with the ability to search specific tools, operators and date range search optimisation.

The reporting system is designed to inform and protect without ever leaving you wanting!

The aftersales service gives organisations the benefit of our extensive vibration risk management experience, complete on-site installation, and on-going support.

For a more detailed look at assumed vibration data compared to continuous measuring and monitoring, download our WHITEPAPER below: